What Are The Procedures (Calculations And Assumptions) To Design A Solar Power Plant?

Introduction:

Today's contemporary world requires energy for a variety of daily uses such as industrial production, heating, transportation, agriculture, and lighting purposes, among others. The majority of our energy needs are often met by nonrenewable sources of energy such as coal, crude oil, natural gas, and so on. However, the exploitation of such resources has had a significant influence on our ecosystem. Furthermore, this type of energy resource is not evenly distributed throughout the planet. Market prices are volatile, as is the case with crude oil, which is dependent on production and extraction from reserves. Because of the scarcity of nonrenewable resources, the demand for renewable resources has increased in recent years.

When it comes to sustainable energy sources, solar energy has received the most attention. It is abundant and readily available, with the availability of tools like solar design software and the ability to supply our whole planet's energy needs. The solar PV system is one method for meeting our energy needs without relying on the utility. As a result, in the following sections, we will look at the planning, design, and installation of a standalone PV system for energy generation.

What Is a Solar PV System?

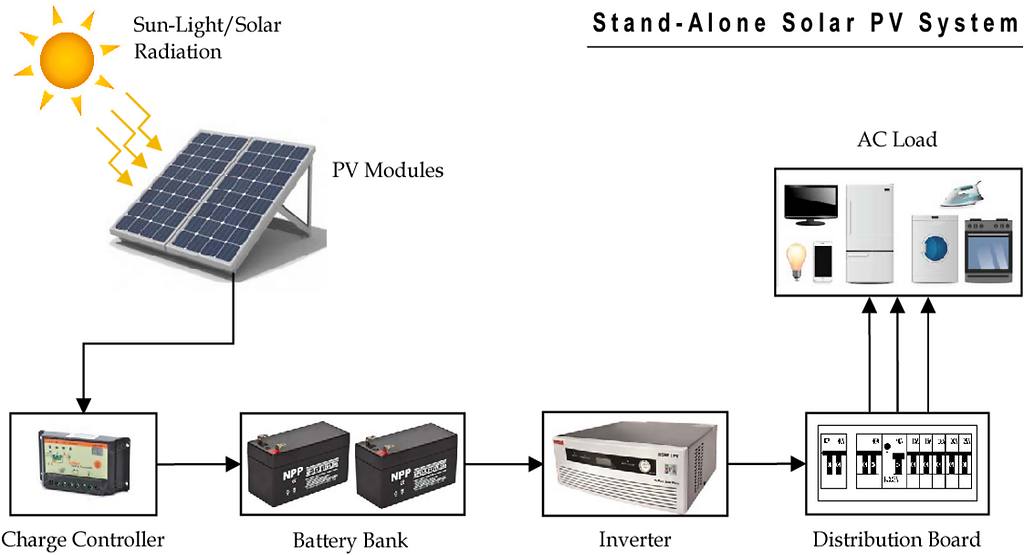

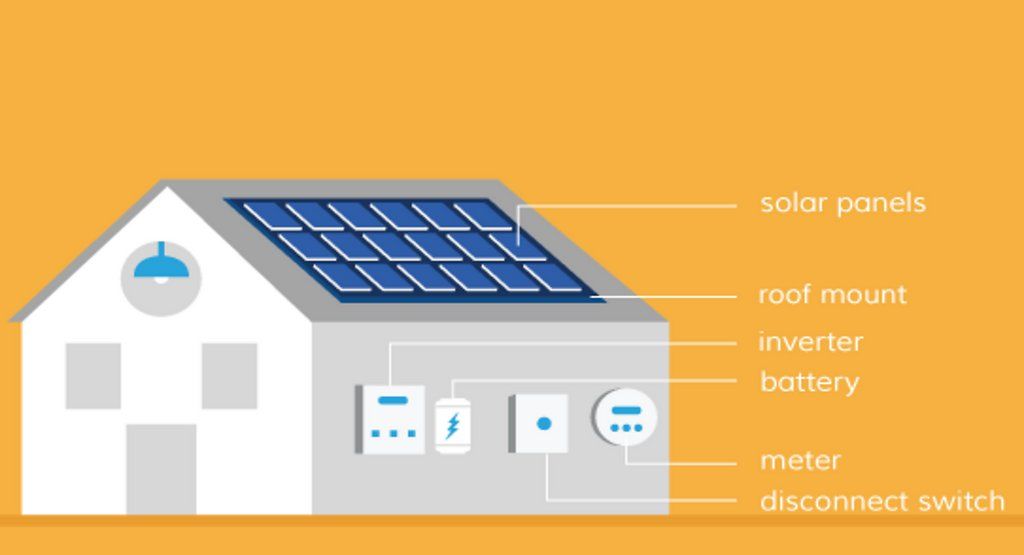

A solar photovoltaic system, often known as a solar PV system, is an electric power system that uses photovoltaics to generate usable solar electricity. It is made up of numerous components, including solar panels to absorb and convert sunlight into energy; a solar inverter to convert the output from direct to alternating current; and mounting, cabling, and other electrical accessories to complete the system. It may also feature an integrated battery and employ solar tracking technology to optimize overall system performance.

PV systems convert light directly into electricity; they are not to be confused with other solar technologies used for heating and cooling, such as concentrated solar power or solar thermal. PV systems range in size from small rooftop-mounted or building-integrated systems with a few to several tens of kilowatts of capacity to big utility-scale power plants with hundreds of megawatts of capacity. Most PV systems are now grid-connected, with off-grid or stand-alone systems accounting for a tiny percentage of the market.

PV systems have evolved from niche market uses to a mature technology utilized for mainstream energy generation, operating silently and with no moving components or environmental pollutants. Over a 30-year service life, a rooftop system recoups the energy spent on construction and installation in 0.7 to 2 years and provides approximately 95% net clean renewable energy.

How To Design Solar PV System:

Do you want to build a solar PV system? Here are the first six steps to getting started:

Figure Out How Much Power You Need:

Arranging a solar system without knowing how much electricity you require is like planning a road trip without knowing how long you will travel or in what vehicle. Now go get some petrol for the journey. How much is it? That depends on your travel distance and petrol mileage. The same goes with solar power. You can't just buy two solar panels and a battery and hope that's enough for your requirements. Enter what you will be powering with your solar power system into our load calculator. You must remember everything that will be powered by your system; seemingly minor modifications might have a significant impact.

Calculator the Amount of Batteries you Need:

Batteries are designed to be stored at temperatures of around 80 degrees Fahrenheit. The larger the battery bank required for below-freezing temperatures, the colder the space. Each of these options has an impact on the size and cost of your battery bank.

Which battery bank voltage do you require—12V, 24V, or 48V? In general, higher voltage battery banks are employed in bigger systems to lower the number of parallel strings and the amount of current flowing between the battery bank and the inverter. A basic 12V battery bank makes sense if you only have a modest system and want to be able to charge your phone and run 12V DC gadgets in your RV. However, if you need to power more than 2000 watts at once, you should look at 24 volt and 48 volt systems. In addition to lowering the number of parallel strings of batteries, it will allow you to employ thinner and less expensive copper cable between the batteries and the inverter.

Calculate the number of Solar Panels needed for your Location and Time of Year:

The second portion of our off-grid calculator can assist you in determining how many solar panels you will require for your solar system. After you've determined how much energy you need to produce every day using the load calculator, you'll need to tell it how much sunlight you'll have to gather. The available solar energy for an area is referred to as "sun hours."

The amount of "sun hours" refers to how many hours the available sun shining at an angle on your panels throughout the day equals sunlight, as if it were shining directly on your solar panels when they are at their most powerful. Because the light isn't as bright at 8 a.m. as it is at noon, an hour of morning sun counts as half an hour, and an hour from midday to 1 p.m. counts as a full hour. And, unless you live near the equator, the amount of sunlight in the winter is not the same as it is in the summer.

You want to use the system in the worst-case situation for your location, the season with the least quantity of sunlight. This way, you won't run out of solar energy throughout the winter.

Select a Solar Charge Controller:

So now that we have batteries and solar, we need to figure out how to get the power from the solar into the batteries. To figure out what size solar charge controller you need, take the watts from the solar panel and divide them by the battery bank voltage. Add an extra 25% for a safety factor.

With the charge controller, there's a little more to think about. There are two basic types of charge controller technologies available: PWM and MPPT. In summary, a PWM charge controller may be used if the voltage of the solar panel array matches the voltage of the battery bank. PWM can therefore be used if you have a 12V panel and a 12V battery bank. If the voltage of your solar panels differs from that of your battery bank and cannot be coupled in series to match, you must use an MPPT charge controller. You must use an MPPT charge controller if you have a 20V solar panel and a 12V battery bank.

Select an Inverter:

Now that we have effectively charged the batteries, we must make the electricity useful. If you are solely running DC loads directly from your battery bank, you may skip this step. However, if you are powering any AC loads, you must convert the direct current from the batteries into alternating current for your appliances. It is critical to understand the sort of AC power required. In North America, the norm is 120/240V split phase, 60Hz. It is 230V single-phase 50Hz across Europe, much of Africa, and certain nations in South America. Some islands have an unusual combination of the two. Some inverters are switchable between voltages and/or frequencies, while others are fixed. So thoroughly examine the specifications of the inverter you're considering to ensure it meets your requirements.

Whether you do have the North American standard, you must determine whether you have any 240V appliances or if they are entirely 120V. Some inverters can output 240V, and the output can be wired to utilize either 120V or 240V. Other inverters are stackable, with each one producing 120V but producing 240V when coupled together or stacked. Others, on the other hand, can only generate 120V and can not be stacked. Read the specifications again to determine which inverter is best for you.

Balance of System:

There are several more minor components required, including:

- The overcurrent protection fuses and breakers

- What breaker boxes will be used

- How will the solar panels be mounted

- What size wire you'll require

Sizing And System Designing of Solar PV Systems:

Calculation of Energy Demand:

The size of a standalone PV system is determined by the load demand. Because the load and running time of different appliances varies, particular care must be given when calculating energy consumption. The energy consumption of the load may be calculated by multiplying the load's power rating (W) by the number of hours of operation. As a result, the unit is abbreviated as watt hour or simply Wh.

Energy demand Watt-hour = Power rating in Watt × Duration of operation in hours.

Thus, the daily total energy demand in Wh is calculated by adding the individual load demand of each appliance per day.

Total energy demand Watt-hour = ∑ (Power rating in Watt × Duration of operation in hours).

Inverter & Converter Ratings:

Using 2.5 kVA as an example, an inverter with a power handling capability 20-30% more than the power operating the load should be selected from the market. Motor load should be 3-5 times more than the power requirement of such an item. The charge controller is rated in current and voltage in the case of the converter. Its current rating is computed using the PV module's short-circuit current rating. The voltage value is the same as the battery's normal voltage.

The charge controller rating should be 125 percent of the short circuit current of the solar panel. In other words, it should be 25% bigger than the solar panel's short circuit current.

Size of solar charge controller in amperes = Short-circuit current of PV × 1.25 (Safety factor).

Due to losses and inverter efficiency issues, the inverter should be 25% larger than the entire load. To put it another way, it should be rated at 125 percent of the total load necessary in watts. For example, if the needed wattage is 2400W, the inverter size should be:

125 percent x 2400W

1.25 x 2400W

3000 Watts of power.

In the case of a 2400W load, we'll require a 3kW inverter.

Daily Energy Supplied To The Inverter:

In our example, the daily energy consumption by the load is 2700 Wh. Because the inverter has an efficiency, the energy provided to it should be greater than the energy consumed by the load, allowing the inverter's losses to be compensated. In our scenario, assuming 90% efficiency, the total energy delivered by the battery to the inverter would be as follows:

Energy supplied by the battery to the inverter input = 2700 / 0.90 = 3000 Wh/per day.

Sizing of Batteries:

Let us consider we have batteries of 12 V, 100 Ah with DOD of 70%. Thus, the usable capacity of the is 100 Ah × 0.70 = 70 Ah. Therefore, the charged capacity that is required is determined as follows;

Required charge capacity = energy supplied by the battery to the inverter input/system voltage

Required charge capacity = 3000 Wh/ 24 V = 125 Ah

From this, the number of batteries required can be calculated as;

No. of batteries required = Required charge capacity / (100 × 0.7)

No. of batteries required = 125 Ah / (100 × 0.7) = 1.78 (round off 2 batteries)

Thus, 2 batteries of 12 V, 100 Ah are required. But due to round off 140 Ah instead of 125 Ah is required.

Required charge capacity = 2 × 100Ah × 0.7 = 140 Ah

Therefore, two 12 V, 100 Ah batteries in parallel to meet the above charge capacity. But as the individual battery is of 12 V, 100 Ah only and the system voltage requirement is of 24 V we need to connect two batteries in series to get the system voltage of 24 V.

So, in total there will be four batteries of 12 V, 100 Ah. Two connected in series and two connected in parallel.

Sizing of PV Array:

Different sizes of PV modules available in the market produce a different level of output power. One of the most common way to determine the sizing of the PV array is to use the lowest mean daily insolation (Solar irradiance) in peak sun hours as follows;

The total size of PV array (W) = (Energy demand per day of a load (Wh) / TPH) × 1.25

Where TPH is the lowest daily average peak sun hours of a month per year & 1.25 is the scaling factor. With this the number of PV modules Nmodules required can be determined as;

Nmodules = Total size of the PV array (W) / Rating of selected panels in peak-watts.

Suppose, in our case the load is 3000 Wh/per day. To know the needed total WPeak of a solar panel capacity, we use PFG factor i.e.

Total WPeak of PV panel capacity = 3000 / 3.2 (PFG) = 931 WPeak

Now, the required number of PV panels are = 931 / 160W = 5.8.

Conclusion:

The solar PV system is a wonderful approach to harness the sun's easily accessible eco-friendly electricity. Its design and installation are simple and dependable for small, medium, and large-scale energy needs. A system like this makes power available practically anywhere across the world, especially in isolated locations. It liberates the energy user from the utility and other energy sources such as coal, natural gas, and so on.

Such a system will have no negative influence on the environment and will produce energy for a long time after it is installed. The aforementioned systematic design and installation give important suggestions for our current world's requirements for clean and sustainable energy.