Mono vs Poly Solar Panels; Choose the Right Technology for your upcoming Solar Rooftop Projects.

Executive Summary

In this study, we make a comparison between a mono PERC (Passivated Emitter and Rear Cell) plant and a poly module solar rooftop installed on the same roof and running at an almost similar capacity. The debate around the use of Polycrystalline vs. Monocrystalline solar panels is ongoing in the rooftop solar sector. Mono PERC modules are costlier, although it has better performance.

In this study, we present an analysis using the generation data provided to us by Chennai-based SolarQuest LLP which does EPC and RESCO projects across India with a portfolio of more than 100 operational projects.

Challenge

The challenge is that it is hard to evaluate whether Mono PERC makes sense from a practical standpoint, even though it has been well proved that Mono PERC has higher efficiencies and energy generation.

We attempt to complete an analysis showing the difference in the generation and based on cost showing the financial payback for both technologies. By the end of the study, we trust you will be able to make your comparison for your projects and can use this study to substantiate to your customers which technology makes better sense for your project

Brief: Monocrystalline vs. Polycrystalline Cells

Monocrystalline Solar Cells

Monocrystalline panels are manufactured from a single silicon crystal structure called an ingot. These panels are solid in their color and have aesthetic appearances as shown in Figure 1.a. Monocrystalline solar panels are made through the Czochralski method, where a silicon crystal ‘seed’ is placed in a container of molten silicon. The seed is then slowly drawn up with the molten silicon forming a solid crystal structure around the seed, called an ‘ingot.’ The ingot of solid crystal silicon that is formed is then finely sliced into a silicon wafer. This is then made into a cell.

Mono PERC solar cells

Passivated Emitter and Rear Cell (PERC) uses dielectric passivation film on the rear surface of the cells as shown in Fig. 1 b. Thus, in PERC cells, the front surface absorbs sunlight while the rear surface absorbs the scattered or reflected light. This results in a higher generation than their traditional counterparts due to higher light absorption and internal reflectivity. When we combine two of the best technologies in the market, they supply even higher energy efficiency of up to 22%.

Polycrystalline solar cells

Polycrystalline panels also start as a silicon crystal ‘seed’ placed in a container of molten silicon. However, rather than drawing the silicon crystal seed up as with monocrystalline, the container of silicon can cool. It is the cooling that forms the distinctive edges and grains within the solar cell as shown in Fig. 1 c.

| Parameter | Monocrystalline | Polycrystalline |

| Efficiency | Higher efficiency rates about 15 – 20% | Lower efficiency about 13 – 16% |

| Space factor | The higher efficiency enables them to deliver better performance in given space. Therefore, very space efficient. | Their lower efficiency rate makes them poor in their performance hence require more space. |

| Heat Tolerance | Performance suffers as temperature goes up but better than polycrystalline panels. | They have lower heat tolerance than mono modules and perform slightly lower than them at high temperatures. |

| Lifespan | Their performance carries for the long run than polycrystalline modules. | Their lifespan is lower to that of monocrystalline modules. |

| Aesthetics | Their uniform and black color makes more attractive. | They tend to be less aesthetically pleasing since they have non-uniform patter and speckled blue color |

| Cost | Cost is higher than the polycrystalline modules. | Cost is lower than mono crystalline modules. |

Table 1. Differences between Monocrystalline and polycrystalline solar cells

Solution

At Solar Labs, we provide software for solar PV design to simplify sales and design processes in rooftop solar installations. Through thousands of installations processed through the software and around 100 MW of technical consultancy, we see growing usage of Mono Perc modules.

SolarQuest LLP is a Chennai-based company doing EPC and RESCO projects across India with a portfolio of more than 100 operational projects. We have inverter monitoring data from the plant and a TSL Studio software simulated annual generation report as the base for our analysis.

The details are provided for an enhanced understanding of the project.

Project details

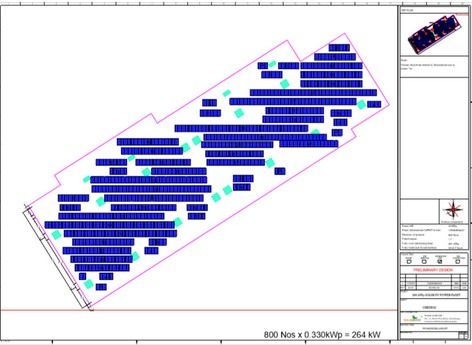

The name of the project is 285 kW (DC)/240 kV AC (Alternating Current) SOLAR PV POWER PLANT, set at the location of 13.035477°N, 80.211188° E installed by SolarQuest in Chennai. The plant has been running since January 2020.

Design

The design layout of the plant installed is portrayed in Figure 2. Both types of modules are installed on the same site so that they experience similar radiation and weather patterns.

Single Line Diagram (SLD)

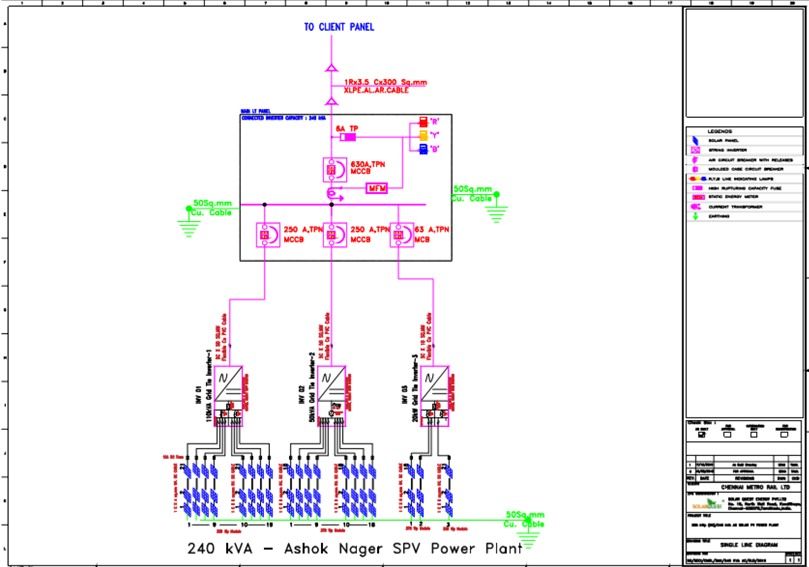

The Single Line Diagram (SLD) for the plant is shown in Figure 2. Here, the electrical layout of the plan is depicted well. Inverter 1 has Mono-PERC (Passivated Emitter and Rear Cell) modules and Inverter 2 has Polycrystalline modules connected to it. On comparing these distinct inverters and plant performances, we produce the term ‘Specific Generation per Rupee Invested’. This term takes into account both generation and financial considerations.

Using this term, you can compare the values and see the delta in the specific generation per additional rupee invested in Mono PERC modules. If the value is greater for mono PERC, go for mono PERC. If the value is greater for Polycrystalline, you should ideally opt for Polycrystalline technology to ensure the highest ROI (Return on investment) for your customer.

Technical information on the Modules and Inverters used in the plant

We provide the datasheet of modules and inverters used.

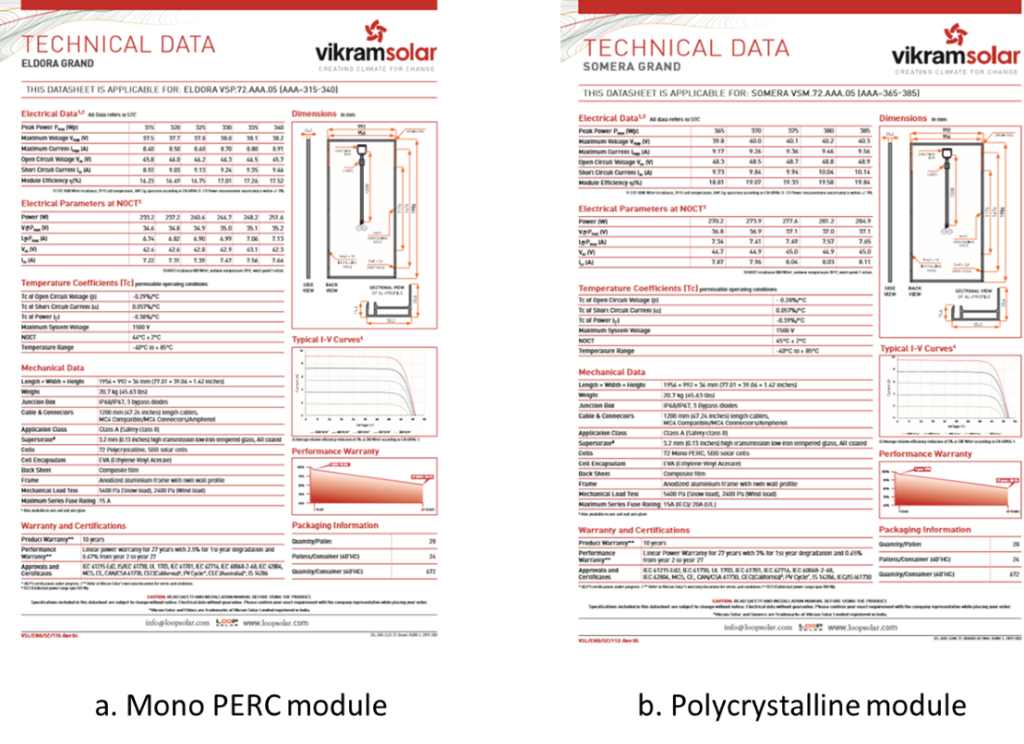

Mono PERC module datasheet

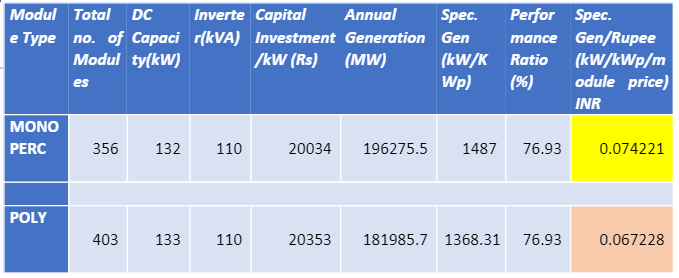

There are 356 modules of mono PERC (370Wp) installed in the PV layout of the rooftop plant.

Polycrystalline module datasheet

There are 403 modules of polycrystalline modules (330Wp) installed on the PV layout of the rooftop plant.

Inverter specifications

Two inverters are installed with each of 110v and 18 and 19 strings of mono PERC and polycrystalline modules, respectively.

Generation Data

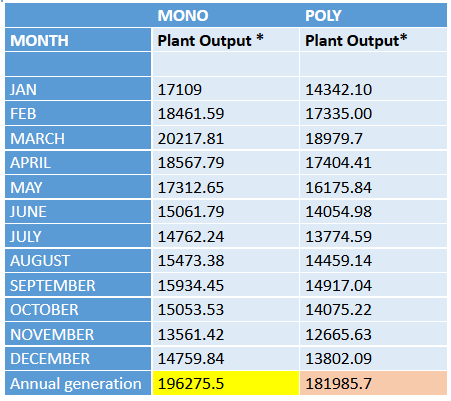

We collected real-time generation data from SolarQuest for the first 6 months of plant life. Since the complete annual data was not available, we then extrapolated data for annual production using the future trend obtained for a similar model designed in ARKA 360 software and created the following table.

Key Performance Indicator (KPI) from this case study

The key feature that is considered for decision-making in this case study is the ‘Specific Generation per Rupee Invested.’ It quantifies the yield of specific generation per kW of the amount spent /Capital investment per kW. We can see that the plant that has mono PERC panels hasae Specific generation per rupee value that is higher than that of the modules made of polycrystalline cells. This depicts the increased performance of Mono PERC modules in the long run.

Analysis

The analysis is done based on the performance of both the plants and the key features are given in the table below,

Calculation

Before diving down to calculation, let us understand the terms involved in measuring the plant design and performance.

| Measure | Criteria | Definition |

| Specific generation | Quality of equipment used and impact of weather. | The total annual production divided by the system DC (Direct Current) nameplate power. |

| Performance ratio (PR) | Quality of the overall design of PV system irrespective of the location. | Ratio of the annual production and Nominal Plant Output, where Nominal Plant output is the product of incident energy on the plant and efficiency of modules. |

| Specific generation per rupee | Cost of generation, panel level. | The yield of specific generation per kW of the amount spent /Capital investment per kW on the modules. |

Definition of performance KPIs

Formulas used

1. Specific generation = Total annual production from the plant/nameplate power. kWh/KWp/year

2. Spec. Gen per rupee= (Power generation from the panel/Capital investment in that panel)

= kWh/kWp * Rupees/kWh = kWp/Rupees

3. Performance ratio Energy measured/ (Total radiation on the panel ∗ Active area of the panel ∗ efficiency)

Extrapolation details that we followed for understanding this study,

- The data available from the plant was only up to 6 months until June 2020. So, we simulated the same model in TSL, Solar Labs software,e and estimated the annual generation trend using Excel formulas as shown below.

- Having these trend values, we substituted the actual output for February month and extrapolated the other values in that column as given below,

- We have the monthly generated trend obtained from TSL for 12 months (say monthly production from TSL as M1, M2, M3…, M12) and 6 months of generation data from SolarQuest( January 25tol June 30). Therefore, we extrapolated the annual plant output by having February month’s data as a base.

- Annual Trend from TSL = (M1/M1, M2/M1, M3/M1…, M12/M1)

- Extrapolation for annual plant output = (February month plant output * trend for the month, February month output * trend for the month, and so on)

- Hereby, we achieved the annual generation figures and calculated the specific generation, performance ratio, and specific generation per rupee criteria

- We have knowingly not considered the cost of land area as a factor in our analysis.

Conclusion

Ever since the development of polycrystalline modules with h drastic reduction in the cost of their modules, there has been this “Monocrystalline Versus Polycrystalline solar cells” debated across the market as well as the researchers.

From this case study, we found some evidence favoring the use of monocrystalline modules for rooftop solar installation. We have created a KPIs called Generation per Capital Investment which considers generation and financial parameters. This KPI is designed to be a simple factor aiding your decision-making process.

- Mono PERC modules perform well within the same weather and irradiance pattern with a specific generation of 1487 kWh/kWp/year while the polycrystalline modules lag by lower specific generation values of 1368.31 kWh/kWp/year.

- Mono PERC plant has INR 0.068 value more in Specific generation per rupee criteria and a 3.55% higher performance ratio than the plant with polycrystalline modules.

- Eventually, we could see that the Mono PERC system requires 47 panels less than the requirement met by installing polycrystalline modules.