Health and Safety concerns related to PV systems

Introduction

As it can be renewable, sustainable, reliable and clean, the photovoltaic industry has proven to be an increasing and advantageous source of power. Important improvements have been made in the materials used and the manufacturing processes to reduce costs and to avoid possible problems caused by certain hazardous materials. However, there are some health and environmental challenges that last, which must be overcome to make this technology a genuinely clean energy source. This article provides an overview of the major environmental impacts associated with the use of toxic materials and chemicals in manufacturing processes, electrical shocks and arc flash, electromagnetic fields (EMF) and lastly fire risks of thin film technology.

Manufacturing toxicity exposure

PV device manufacturing includes some chemicals which can be toxic or harmful to humans. The potential for health concerns depends not only on the harmful material characteristics but also on certain conditions that must be taken into consideration. For example, in addition to the harmful characteristics of the chemicals, their concentration must be sufficiently high to constitute a real problem in a given environment: a human or an animal must be in the environment where the device or compound is used; a total process of exposure from the compound to the environment must take place. The plant workers are most often the primary people exposed to residues from the production of photovoltaics. For workers, the easiest route of exposure is inhalation of vapours or dusts, and also through direct contact if spills occur. Accidental ingestion could be another route for workers to be infected with chemicals resulting from manufacturing processes. Chemicals could infect those outside a manufacturing environment through inhalation from stack emissions, elusive air emissions or accidental release after fire or explosion. But the exposure of nearby residents or other workers would be less than that of plan workers because after their emission the chemicals would be dispersed in the ambient air. There are possibilities for environmentally polluting lands containing spent PV modules. For example, groundwater seepage could reach a drinking water source or river in the surroundings of spent PV modules; but in both cases the waste would be diluted (not entirely) before the water was used. In short, before reaching nearby residents, any vapour or groundwater inlet would be diluted by the ambient air or water. It is well known that the manufacture of PV cells and modules requires the use of more or less large quantities of solvents and acids for synthesis and cleaning, gases for the deposition of ultra-thin film of materials and metals of semiconductors according to the type of PV cell or module being manufactured. Most of these chemicals are highly toxic to humans and to the environment. Some health and environmental issues caused by chemical hazards related to the toxicity, flammability, explosivity and carcinogenic nature of the materials are discussed below.

1] Cadmium Telluride (CdTe): CdTe solar cell manufacturing can cause occupational health risks associated with the toxicity of major constituent materials such as CdTe, CdS, and cadmium chloride (CdCl2). Since cadmium compounds are usually used in powder and liquid form, in manufacturing settings the primary route of exposure is inhalation of cadmium-containing vapours or dust or ingestion of spills where this occurs. Processes in which cadmium compounds are used or produced in the form of fine fumes or particles pose more health risks as they promote the absorption by the lung of these fine particles and hence can cause a lung cancer. Long-term exposure can also cause harm to the bone and kidney. Additionally, inhalation of vapours or dusts containing cadmium can lead to metal vapour fever, pneumonitis, respiratory failure, and eventually death. Since cadmium is produced primarily as a by-product of zinc mining, the production levels of Cd are fixed by the production levels of zinc. Because Zn is produced in large quantities, considerable quantities of Cd are also generated as a by-product, without taking into consideration the quantity used or required in PV technology. If the quantity of Cd generated as a zinc by-product is not fully absorbed by the entire market, it is discharged as hazardous waste to the environment. Thus, for the manufacture of PV modules, encapsulating Cd in CdTe could be a trusty way to preserve the environment of hazards that can cause free elemental Cd. CdTe is more stable and water-insoluble; as such it could be less toxic or harmful than free elemental Cd.

2] Amorphous silicon (a-Si): Solar cells based on amorphous silicon are generally manufactured using the technique of plasma-enhanced chemical vapour deposition (PECVD). Silane gas (SiH4), mainly used as a precursor, is extremely pyrophoric, and represents this technology ‘s main safety hazard. It can ignite spontaneously depending on the carrier gas for lower concentrations ranging from 2 to 3 %. Pyrophoric footprints can be found locally if mixtures are not complete due to the high pyrophoric nature of silane and even for concentrations below 2 % in carrier gas. Mixtures could be metastable and ignited for concentrations of silane greater than 4.5% after a certain time. Amorphous silicon solar cells contain about 10% of the high concentration of hydrogen atoms, as they are crucial to the electronic properties of the material. However, the technology usually refers to using the words “amorphous silicon” rather than “hydrogenated amorphous silicon (a-Si:H),” because “un-hydrogenated amorphous silicon” is of no use in electronic devices. Hydrogen used in the production of amorphous silicon is explosive and flammable; therefore, highly sophisticated gas handling systems need to be used by PV manufacturers to minimise and even avoid the risks of fire and explosions.

Electric shocks and Arc flash

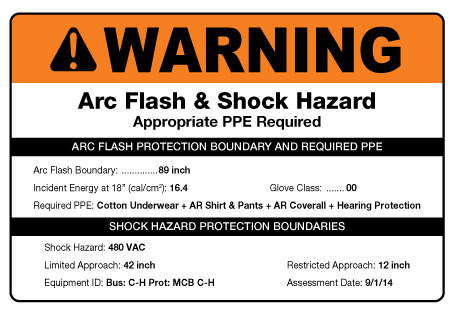

Anyone entering any of the electrical cabinets such as combiner boxes, disconnect switches, inverters, or transformers is in real danger of electrical shock; or otherwise coming into contact with voltages over 50 Volts. Another electrical hazard is an arc flash, an explosion of energy that can occur in a short circuit situation. This explosive release of energy causes a heat flash and a shock wave which can both cause serious injury or death. Properly trained and equipped technicians and electricians are able to install, test and repair PV systems safely, but when hazardous voltages and/or currents are present, there is some risk of injury. Untrained personal should not attempt to inspect, test or repair any aspect of a PV system because of the potential for injustice or death due to electrical shock and arc flash, the National Electric Code (NEC) requires adequate levels of warning signs on all electrical compounds based on the level of danger determined by voltages and current potential. The National Electrical Code (NEC) also requires that the site be secured from unauthorised visitors with either a six-foot chain connecting fence with three barbed wire strands or an eight-foot fence, both with adequate warning signs.

Electromagnetic fields (EMF)

Some have expressed concern over potential health effects of EMF from electricity since the 1970s, but no studies have ever shown that this EMF causes health problems. These concerns are based on certain epidemiological studies that found a slight increase in childhood leukaemia associated with average exposure to residential power-frequency magnetic fields above 0.3 to 0.4μT(micro-teslas), and mG are both units used to measure the strength of the magnetic field. For comparison, the average U.S. people exposure. This is one mG or 0.1μT, with an average exposure of about 1% of the population exceeding 0.4μT (or 4 mG).64 These epidemiological studies, which found an association but not a causal relationship, led the International Agency for Research on Cancer (IARC) of the World Health Organization to classify ELF magnetic fields as ‘possibly carcinogenic to humans’. Overall, there is very little concern that ELF EMF damages public health.

During their operation, PV systems do not emit any material; however, they do generate electromagnetic fields (EMFs), sometimes called radiation. EMF produced by electricity is non-ionizing radiation, meaning that the radiation has sufficient energy to move atoms around a molecule (experienced as heat), but not enough energy to remove electrons from an atom or molecule (ionise) or to damage DNA; Without negative impact on health, modern humans are all exposed to EMF throughout our daily lives. Someone outside a solar facility’s fenced perimeter is not exposed to significant EMF from the solar installation. Therefore, the EMF produced in a solar farm has no negative health impact.

Fire risks

The possibility of fires resulting from or intensified by photovoltaic systems can cause concern both among the general public and among firefighters. However, concern over solar fire hazards should be limited, as only a small portion of the materials in the panels are flammable, and those components cannot sustain a significant fire on their own. Flammable components of photovoltaic panels include thin layers of polymer encapsulates surrounding the PV cells, polymer back sheets, plastic junction boxes on the back of the panel, and wiring insulation. The rest of the panel consists of non-flammable components, notably one or two layers of protective glass that make up more than three quarters of the weight of the panel. Heat from a small fire is not sufficient to ignite a PV panel, but heat from an intensified fire or energy from an electrical failure can ignite a PV panel.

PV systems on buildings can affect firefighters in two main ways:

1) affect their fire-fighting methods.

2) pose safety hazard to firefighters.

One of the most significant techniques used by firefighters to suppress fire is ventilation of the roof of a building. This technique allows quick exit of the building by super-heated toxic gases. The firefighters thus gain easier and safer access to the building, Ventilation of the roof also facilitates the challenge of putting out the fire. Placing rooftop PV panels can, however, interfere with ventilating the roof by restricting access to desired ventilation locations.

Conclusion

In conclusion, the aim of this article is to address and alleviate public health and safety concerns for solar photovoltaic projects on a utility scale. Public health and safety concerns were broken down and discussed in the following four sections: (1) Toxicity, (2) Electromagnetic Fields, (3) Electric Shock and Arc Flash, and (4) Fire. The negative health and safety impacts of utility-scale PV development have been shown to be negligible in each of these sections, while the public health and safety benefits of installing such facilities are significant and far outweigh any negative impacts.